2024.09.02

FEDERAL CLASSROOM EP16- lectroplating Technology: A Surface Treatment Method in the Lock Industry

Article classification: FEDERAL CLASSROOM

FEDERAL CLASSROOM EP16

Electroplating Technology: A Surface Treatment Method in the Lock Industry

你不知道的鎖事 知識篇 - 電鍍技術:鎖具行業的表面處理方法

Electroplating Process: Principles and Procedures

電鍍工藝:原理與流程

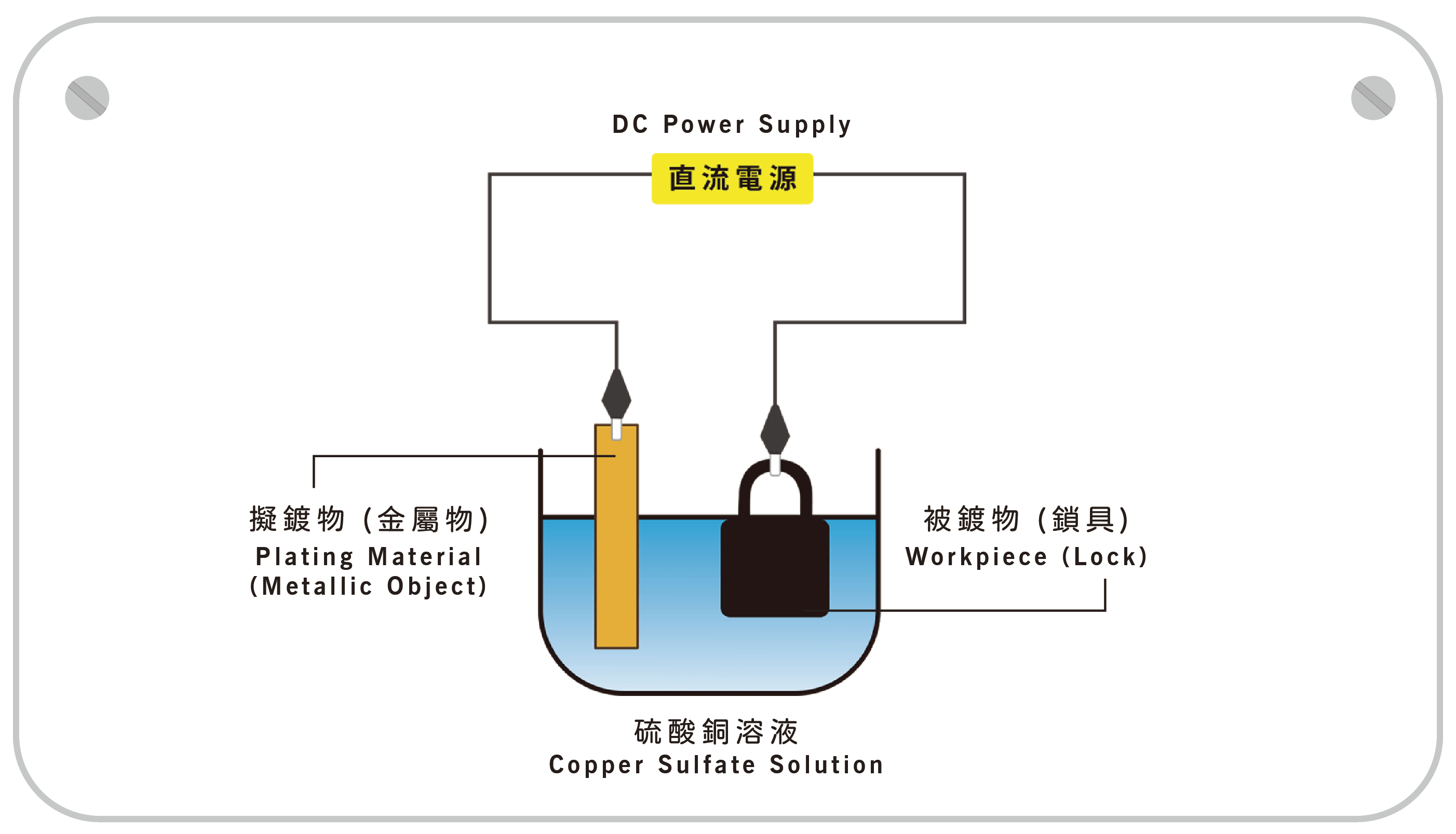

Electroplating is a precision surface treatment technique that forms a metal layer on a substrate using electrochemical principles. This process involves complex electrochemical reactions and requires precise control over multiple variables to achieve the desired outcome. During electroplating, the metal to be plated (the cathode) is immersed in a specially formulated electrolyte containing ions of the desired coating metal. When direct current is applied, metal ions in the electrolyte are attracted to the cathode and undergo a reduction reaction, resulting in the formation of a dense and uniform metal film.

電鍍是一種精密的表面處理技術,利用電解原理在金屬表面形成另一種金屬層。這個過程涵蓋複雜的電化學反應,需要精確控制多個數值才能達到理想效果。在電鍍過程中,待鍍金屬(陰極)被浸入特製的電解液中,這種液體含有所需鍍層金屬的離子。當直流電通過電解槽時,電解液中的金屬離子被吸引到陰極表面並發生還原反應,形成緊密且均勻的金屬薄膜。

This highly controllable surface treatment method not only enhances the substrate's corrosion resistance but also significantly improves the product's performance. By adjusting the current density, electrolyte composition, and plating time, one can precisely control the thickness and properties of the electroplated layer, thereby optimizing the surface's smoothness and aesthetic appeal. Additionally, electroplating can extend the product's lifespan, ensuring stable performance in various harsh environments.

這種高度可控的表面處理方法不僅能夠提高基材的耐腐蝕性,還能顯著改善產品的性能。通過調整電流密度、電解液成分和電鍍時間,可以精準控制電鍍層的厚度和性質,從而優化表面的光潔度和美觀度。此外,電鍍還能夠延長產品的使用壽命,使其在各種惡劣環境下保持穩定性能。

The Value of Electroplating in the Lock Industry

電鍍在鎖具行業的應用價值

In the realm of lock manufacturing, electroplating has become an indispensable process. Its value extends far beyond mere surface beautification, contributing to comprehensive improvements in product performance. By electroplating metals such as zinc, nickel, or chrome, locks achieve significantly enhanced corrosion resistance and wear durability. This means that even in environments with high humidity, salt, or industrial pollution, locks can maintain their functionality and appearance.

在鎖具製造領域,電鍍已經成為一項不可或缺的技術。它的應用價值遠超過簡單的表面美化,而是對產品性能的全面提升。通過電鍍鋅、鎳、鉻等金屬,鎖具的抗腐蝕能力和耐磨性得到顯著提高。這意味著即使在高濕度、高鹽分或工業污染嚴重的環境中,鎖具也能保持其功能和外觀。

Electroplating also brings unprecedented customization capabilities to the lock industry. Manufacturers can easily adjust the product's gloss, color, or even texture to meet market demands and design trends. This flexibility allows locks to transcend their functional role, becoming integral elements of architecture and interior design.

電鍍還為鎖具行業帶來了前所未有的外觀客製能力。製造商可以根據市場需求和設計趨勢,輕鬆調整產品的光澤度、顏色甚至紋理。這種靈活性使得鎖具不再僅僅是功能性的配件,而是成為建築和室內設計的重要元素。

From an economic perspective, electroplating is often more cost-effective than other surface treatment methods, especially in large-scale production. It allows for high-quality locks to be produced while effectively controlling manufacturing costs, making superior lock products more accessible.

從經濟角度來看,電鍍通常比其他表面處理方法更具成本效益,特別是在大批量生產中。它能夠在保證質量的同時,有效控制生產成本,使高品質的鎖具產品更加普及。

Common Electroplating Techniques in the Lock Industry and Their Characteristics

鎖具行業常用電鍍工藝及其特點

US32D (Satin Stainless Steel)

Commonly referred to as satin stainless steel, US32D is a highly favored surface treatment in the lock industry. This process involves more than just electroplating; it encompasses a series of meticulous surface treatment steps. Initially, high-quality stainless steel undergoes rigorous polishing to remove all surface imperfections. Then, precise brushing or sandblasting creates a uniformly fine texture, resulting in a smooth satin finish.

通常被稱為緞面不銹鋼處理,是鎖具行業中備受青睞的表面處理方式。這種工藝不僅僅是簡單的電鍍,而是涵蓋一系列精細的表面處理步驟。首先,高品質的不銹鋼基材經過嚴格的拋光處理,去除表面所有的微小缺陷。而後進行精密控制的拉絲或噴砂製程,在表面形成均勻的細微紋理,產生柔和的緞面效果。

The outcome of this electroplating is a unique surface texture that combines the toughness of metal with a soft sheen. Locks treated with US32D not only boast corrosion resistance, effectively withstanding various chemical erosions encountered in daily use but also offer excellent fingerprint resistance, making them easy to clean and maintain. This surface treatment is particularly well-suited for locks used in high-traffic environments, such as commercial buildings, medical facilities, or upscale residential properties.

這種電鍍的效果是一種獨特的表面質感,既有金屬的堅硬感、又帶有柔和的光澤。US32D處理的鎖具不僅具有耐腐蝕性,能夠抵抗日常使用中的各種化學侵蝕,還能夠優秀的抗指紋,易於清潔維護。而這種表面處理的鎖具也特別適合使用在會平凡使用的場景,如商業建築、醫療設施或高端住宅。

US26D (Satin Chrome)

Also known as satin chrome, US26D is another widely used surface treatment in the lock industry. This technique involves a complex multi-layer electroplating process. First, a layer of copper is electroplated onto the substrate to provide a base for subsequent layers. Next, a nickel layer is applied, adding extra corrosion resistance and hardness. Finally, a thin, uniform layer of chrome is electroplated on the surface, imparting the product with its distinctive appearance and performance.

或稱緞面鉻處理,是另一種廣泛應用於鎖具的表面處理技術。這種技術涉及複雜的多層電鍍過程。首先需要在基材表面電鍍一層銅作為後續鍍層的基底。接著進行鎳層電鍍,提供額外的耐腐蝕性和硬度。最後一層薄而均勻的鉻被電鍍在表面,賦予產品獨特的外觀和性能。

The chrome layer not only offers a sleek, modern look but also delivers exceptional wear resistance and chemical stability. The satin finish further enhances the surface's scratch resistance while creating a subtle luster. This treatment is particularly suitable for both indoor and outdoor environments, capable of displaying different visual effects under varying lighting conditions, adding depth and richness to architectural design.

鉻層不僅提供了現代簡約的外觀,還具有卓越的耐磨性和化學穩定性。緞面處理進一步增強了表面的抗刮能力,同時創造出柔和的光澤。這種處理方式特別適合各種室內外環境,能夠在不同光線條件下呈現出不同的視覺效果,為建築設計增添了豐富的層次感。

Nickel Plating 鍍鎳

Nickel plating is one of the most versatile electroplating techniques in the lock industry. This process involves electrolysis in an acidic or alkaline nickel salt solution, depositing a layer of pure nickel onto the substrate. Every parameter of the nickel plating process, including current density, temperature, pH level, and additives, impacts the final properties of the coating.

鍍鎳是鎖具行業中最多功能的電鍍工藝之一。這種工藝通過在酸性或鹼性的鎳鹽電解液中進行電解,在基材表面沉積一層純鎳。鍍鎳過程的每一個參數,包括電流密度、溫度、pH值和添加劑的使用,都會對最終鍍層的性質產生影響。

One standout feature of nickel plating is its customizability. By adjusting plating parameters, a range of gloss levels can be achieved, from matte to mirror-like finishes. This flexibility makes nickel plating a preferred surface treatment for many high-end locks. Additionally, the ductility of the nickel layer ensures that even on moving parts of locks, the coating remains resistant to cracking or peeling.

鍍鎳的一個明顯特點是其可客製性。通過調整電鍍參數,可以實現多種光澤度,從啞光到鏡面光澤不等。這種靈活性使得鍍鎳成為很多高端鎖具的首選表面處理方式。此外,鎳層的延展性代表著即使在鎖具的活動零件上,鍍層也不易開裂或剝落。

Nickel plating is also renowned for its excellent corrosion resistance, effectively protecting the substrate in various environments. This makes it an ideal choice for locks used in coastal areas or industrial settings. Notably, nickel plating is often used as an underlayer for other electroplating processes, providing an ideal foundation for subsequent treatments.

鍍鎳還以其優異的耐蝕性而聞名,能夠有效防止基材在各種環境下的腐蝕。這使得鍍鎳成為海濱地區或工業環境中鎖具的理想選擇。值得一提的是,鍍鎳常常作為其他電鍍工藝的底層,為後續處理提供理想的基礎。

Zinc Plating 鍍鋅

Zinc plating is one of the most widely applied electroplated techniques in the lock industry, particularly for mass-produced steel locks. This process involves electrolysis in an alkaline cyanide or acidic chloride electrolyte, forming a uniform zinc layer on the steel surface. The primary purpose of zinc plating is to provide superior corrosion protection.

鍍鋅是鎖具行業中應用最為廣泛的電鍍工藝之一,特別是對於大批量生產的鋼鐵鎖具。這種工藝通過在鹼性氰化物或酸性氯化物電解液中進行電解,在鋼鐵表面形成一層均勻的鋅層。鍍鋅的主要目的是提供卓越的防腐蝕保護。

In corrosive environments, the zinc layer reacts preferentially over the steel substrate, thereby protecting the substrate from corrosion. This protective mechanism ensures that even with minor surface damage, zinc-plated locks can maintain strong corrosion resistance.

在腐蝕性環境中,鋅層會優先於鋼鐵基材發生反應,從而保護基材免受腐蝕。這種保護機制使得鍍鋅鎖具即使在表面受到輕微損傷的情況下,仍能保持良好的防腐性能。

The surface of the zinc-plated products typically exhibits a silver-white appearance, but post-treatment with chromate can achieve a variety of colors, such as blue, black, or olive. This treatment not only enhances the product's decorative appeal but also further improves its corrosion resistance. Another advantage of zinc plating is its excellent adhesion, making it an ideal base for subsequent painting or other surface treatments.

鍍鋅後的表面通常呈現銀白色,但通過後續的鉻酸鹽處理,可以獲得多種顏色選擇,如藍色、黑色或橄欖色。這種處理不僅增加了產品的裝飾性,還進一步提高了表面的耐腐蝕能力。鍍鋅的另一個優勢是其良好的附著力,這使得它成為後續塗裝或其他表面處理的理想基底。

Comprehensive Performance Enhancement of Locks Through Electroplating

電鍍對鎖具性能的全面提升

Electroplating technology offers a holistic improvement in lock performance. In terms of corrosion resistance, the protective layer formed through electroplating effectively shields the substrate from corrosive substances in the environment. This means that even in high-humidity, high-salinity, or chemically polluted environments, locks can retain their original functionality and appearance. This anti-corrosion capability is especially crucial for outdoor locks, significantly extending product longevity.

電鍍技術對鎖具性能的提升是全方位的。在耐腐蝕性方面電鍍形成的保護層能夠有效阻隔環境中的腐蝕性物質與基材的接觸。這代表即使在高濕度、高鹽分或化學污染嚴重的環境中,鎖具也能保持其原有的功能和外觀。這種抗腐蝕能力對於戶外使用的鎖具尤為重要,大大延長了產品的使用壽命。

In terms of wear resistance, certain electroplating techniques, such as chrome plating, can substantially enhance the hardness of the lock's surface. This hardening process enables locks to withstand friction and impact from daily use, reducing surface scratches and wear. For locks used in high-traffic commercial or public spaces, this wear resistance is vital, ensuring that the locks maintain their appearance and functionality over the long term.

在耐磨性方面,某些電鍍工藝如鉻鍍可以顯著增強鎖具表面的硬度。這種硬化處理使得鎖具能夠承受日常使用中的摩擦和碰撞,減少了表面的刮痕和磨損。對於高頻率使用的商業或公共場所的鎖具來說,這種耐磨性能很重要,可以確保鎖具長期保持良好的外觀和功能。

Electroplating also noticeably extends the lifespan of locks. By providing comprehensive surface protection, electroplating reduces the wear and corrosion of lock components, decreasing the frequency of maintenance and replacement. This not only saves maintenance costs but also enhances user satisfaction. For built-in locks that are difficult to replace or maintain, this longevity feature is especially important.

電鍍還能明顯延長鎖具的使用壽命。通過提供全面的表面保護,電鍍減少了鎖具零件的磨損和腐蝕,降低了維護和更換的頻率。這不僅節省了維護成本,還提高了用戶的使用滿意度。對於一些難以更換或維護的內置鎖具,這種長壽命特性尤為重要。

In terms of aesthetics, electroplating technology offers a wealth of creative possibilities. From mirror-like chrome surfaces to soft satin finishes, and even to vibrant decorative electroplating, customers can choose the most suitable surface treatment based on architectural style and personal preference.

在美觀度方面,電鍍技術提供了豐富的創意空間。從光亮如鏡的鉻鍍表面到柔和的緞面處理,再到多彩的裝飾性電鍍,客戶可以根據建築風格和喜好選擇最合適的表面處理方式。

Electroplating technology has become an indispensable part of the lock industry, not only enhancing product quality and durability but also introducing unprecedented diversity to the market. With increasing environmental requirements and the emergence of new materials, electroplating technology is continuously evolving, moving towards more environmentally friendly, efficient, and refined applications.

電鍍技術已經成為鎖具行業不可或缺的一部分,它不僅提高了產品的品質和耐用性,還為市場帶來了前所未有的多樣化選擇。隨著環保要求的提高和新材料的出現,電鍍技術也在不斷進步,朝著更加環保、高效和精細化的方向發展。

Overall, electroplating technology will continue to play a critical role in lock manufacturing, driving the industry towards higher quality and broader applications, providing solid protection for our safety and quality of life.

總的來說,電鍍技術將繼續在鎖具製造中扮演關鍵角色,推動行業向更高質量、更廣泛的應用方向發展,為我們的安全和生活品質提供了堅實的保障。